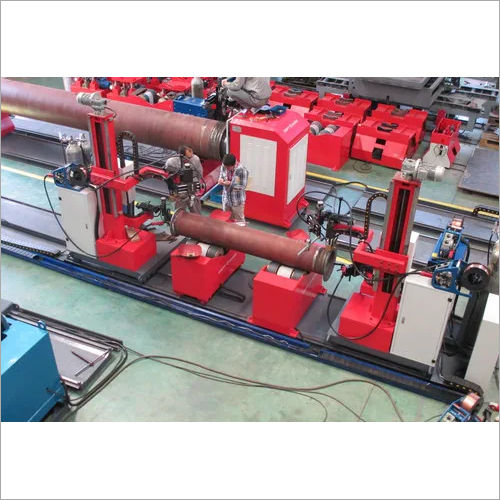

Automated Pipe Welding Machine

25000.00 - 40000.00 USD ($)/Set

Product Details:

- Condition New

- Motor Type AC Motor

- Material Stainless Steel

- Product Type Pipe Welding Machine

- Weight 234 Kilograms (kg)

- Color Red and Gray

- Voltage 380/220 Volt (v)

- Click to View more

X

Automated Pipe Welding Machine Price And Quantity

- 25000.00 - 40000.00 USD ($)/Set

- 1 Set

Automated Pipe Welding Machine Product Specifications

- 1800*1200*2300 Centimeter (cm)

- Red and Gray

- Stainless Steel

- New

- Pipe Welding Machine

- 380/220 Volt (v)

- AC Motor

- 234 Kilograms (kg)

Automated Pipe Welding Machine Trade Information

- 20 Set Per Month

- 45 Days

Product Description

Pipe automatic welding machine is a specialized tool used in the welding industry for joining sections of pipes together. These machines are designed to automate and facilitate the welding process, making it more efficient, consistent, and precise.Automated Pipe Welding MachineApplications: 1. Oil and Gas Industry: pipe automatic welding machine are extensively used in the oil and gas sector for fabricating pipelines, both onshore and offshore. These pipelines transport crude oil, natural gas, and refined petroleum products. Welding machines ensure the integrity and reliability of the pipelines, which are critical for the safe and efficient transportation of these commodities.2. Construction: In construction projects, pipe welding machines are used for joining pipes for plumbing, heating, ventilation, and air conditioning (HVAC) systems. They are also used in structural welding applications for building frameworks, supports, and other infrastructure components.3. Water and Wastewater Treatment: Pipe welder machines play a crucial role in the construction and maintenance of water and wastewater treatment facilities. They are used for joining pipes that transport potable water, wastewater, and industrial effluents, ensuring the efficient operation of these facilities.4. Power Generation: pipe automatic welding machine are utilized in power generation facilities for constructing pipelines that transport water, steam, and other fluids necessary for electricity generation. They are also used in the fabrication of heat exchangers, boilers, and other components in thermal and nuclear power plants.5. Chemical and Petrochemical Industry: In chemical and petrochemical plants, pipe welding machines are used for joining pipes and fittings that transport various chemicals, gases, and liquids. These pipelines are essential for the production, processing, and transportation of chemical products.6. Mining and Minerals Processing: Pipe automatic welding machine are employed in the mining industry for constructing pipelines that transport ores, slurries, and process fluids in mining and minerals processing operations. These pipelines are crucial for the extraction, beneficiation, and transportation of minerals and metals.7. Shipbuilding and Marine Applications: In shipbuilding and marine industries, pipe welding machines are used for fabricating piping systems for ships, offshore platforms, and marine structures. These systems include fuel lines, hydraulic systems, cooling systems, and other essential components.8. Infrastructure and Transportation: Pipe welder are used in infrastructure projects such as road and bridge construction, tunneling, and railway development for constructing drainage systems, culverts, and utility pipelines.9. Agriculture: In agricultural applications, pipe welding machines are used for building irrigation systems, drainage systems, and other agricultural infrastructure.Automated Pipe Welding MachineFeatures: 1. On-line Performance: Good (Designed as per the one line equipment of the production line)2. Welding Efficiency: Excellent (100150 inch/day, which is 4 times higher than the manual welding)3. Operability: Very good (applicable and easy to operate even if you are a new user within a short period of time)4. Surface finishing: Good (the welding gun will always be positioned in the optimum position)5. Welding compliance rate: 98% min (without re-working for the skilled operator).6. Driving Reliability: Good (driven with friction; the necessary balance weight shall be provided for the pipe with DN600 and which the wallthickness is 40 to balance the serious eccentricity resulted from bending).Automated Pipe Welding MachineSpecifications: 1. Pipe diameter applicable: DN400800(426810)2. Pipe wall thickness applicable: 1880MM3. Welding line applicable: Various welding lines of tube sections such as tube tube, tube elbow, tube flange, flange flange and flange elbow, etc (a fake pipe transition connection shall be applied if necessary).4. Driving system: Two rows of metal plus rubber compound idler wheel driven by motor.5. Clamping system: Clamping with double chain clamping mechanism6. Bracket System: Separate type of trolley matching for welding machine, which may be adjusted along the track according to the length of the pipeline.7. Counterweight System: Nil8. Speed regulation Mode: VF stepless speed control system9. Control system: Aproduct of our patented technology.10. Welding mode: Thick and single double wire SAW.11. Materials applicable: Carbon steel, alloy steel, stainless steel and cryogenic steel12. Core Components: PLC, Engine, Motor13. Current: 70-800A14. Rated Capacity: 30KW15. Rated Duty Cycle: 120%16. Certification: ISO, CE17. Video outgoing-inspection: Provided18. Machinery Test Report: Provided19. Warranty of core components: 1 YearFAQs ofAutomated Pipe Welding Machine: Q. What is an pipe automatic welding machine?Ans: An automated pipe welding machine is a piece of equipment designed to perform welding on pipes without direct manual intervention. It utilizes robotic or mechanized systems to carry out welding processes efficiently and consistently.Q. How does an automated pipe welding machine work?Ans: pipe automatic welding machine typically consist of a welding power source, welding torch or welding head, manipulator or robotic arm, and a control system. The machine is programmed to follow specific welding paths, ensuring precise and repeatable welds.Q. What types of pipes can be welded using automated machines?Ans: Automated pipe welding machines are versatile and can be used for welding various types of pipes, including carbon steel, stainless steel, and alloy pipes. They are employed in industries like oil and gas, construction, and manufacturing.Q. What are the advantages of using automated pipe welding machines?Ans: Advantages include increased efficiency, consistent and high-quality welds, reduced labor costs, improved safety, and the ability to work in hazardous or challenging environments.Q. Can pipe automatic welding machine be used for different welding processes?Ans: Yes, automated pipe welding machines can be configured for various welding processes such as Gas Tungsten Arc Welding (GTAW), Gas Metal Arc Welding (GMAW), Flux-Cored Arc Welding (FCAW), and Submerged Arc Welding (SAW), depending on the application requirements.Q. How is the programming done for automated pipe welding machines?Ans: Programming can be done using dedicated software that allows users to input parameters such as welding paths, speeds, and other variables. Some systems may also use teach pendant programming where the operator guides the robotic arm through the desired welding path.Q. What safety measures should be taken when using pipeautomated pipe welding machine?Ans: Safety measures include ensuring proper machine maintenance, providing adequate training for operators, implementing emergency stop features, and following all safety guidelines outlined by the machine manufacturer.Q. What is the role of inspection and quality control in an automated pipe welding machine?Ans: Inspection and quality control are crucial aspects of automated pipe welding. Non-destructive testing methods such as X-rays, ultrasonic testing, and visual inspections are commonly used to ensure the integrity of the welds.Q. Can pipe automatic welding machine be integrated into existing production lines?Ans: Yes, many of these machines are designed to be easily integrated into existing production lines. Compatibility and integration depend on the specific machine and production setup.Q. What are the maintenance requirements for Automated Pipe Welding Machine?Ans: Regular maintenance, including checking and replacing consumables, inspecting robotic arms or manipulators, and ensuring proper calibration, is essential to keep these machines in optimal working condition.FAQs of Automated Pipe Welding Machine:

Q: What type of motor is used in the Automated Pipe Welding Machine?

A: The Automated Pipe Welding Machine is equipped with an AC motor.Q: What are the dimensions of the Automated Pipe Welding Machine?

A: The dimensions of the machine are 1800*1200*2300 centimeters (cm).Q: What is the weight of the Automated Pipe Welding Machine?

A: The machine weighs 234 kilograms (kg).Q: What material is the Automated Pipe Welding Machine made of?

A: The machine is made of stainless steel.Q: What is the voltage requirement for the Automated Pipe Welding Machine?

A: The voltage required for the machine is 380/220 volts (v).Q: What are the colors available for the Automated Pipe Welding Machine?

A: The machine is available in red and gray colors.Q: Is the Automated Pipe Welding Machine in new condition?

A: Yes, the machine is in new condition.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry