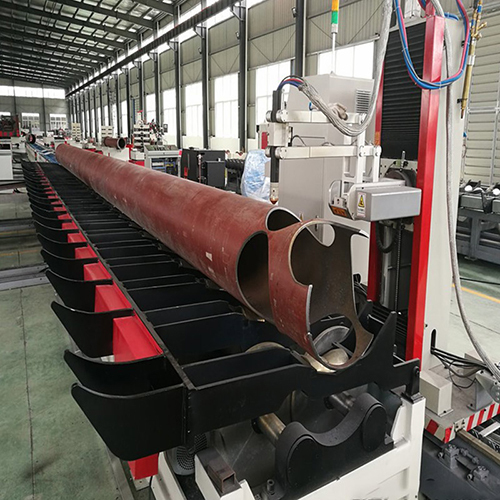

CNC Pipe Cutting Machine

4999.00 - 9999.00 USD ($)/Set

Product Details:

- Operating Type Automatic

- Usage & Applications Industrial

- Click to View more

X

CNC Pipe Cutting Machine Price And Quantity

- 1 Set

- 4999.00 - 9999.00 USD ($)/Set

CNC Pipe Cutting Machine Product Specifications

- Industrial

- Automatic

CNC Pipe Cutting Machine Trade Information

- 10 Days

Product Description

A CNC (Computer Numerical Control) pipe cutting machine is a specialized piece of equipment used in manufacturing and fabrication processes to cut pipes and tubes with precision and efficiency. These machines are equipped with computer-controlled systems that allow for automated cutting operations based on programmed instructions.

Here are some key features and components of a typical CNC pipe cutting machine:

1. Computer Control: The heart of the CNC pipe cutter is its computer control system. This system interprets design specifications from CAD (Computer-Aided Design) software and translates them into cutting instructions.

2. CAD/CAM Software: computer numerical control pipe cutting machines are often paired with CAD/CAM software, which allows operators to design and program cutting paths. The software generates the necessary code for the CNC machine to execute the cuts.

3. Cutting Mechanism: CNC pipe cutting machines employ various cutting mechanisms depending on the specific application and requirements. Common cutting methods include plasma cutting, oxy-fuel cutting, laser cutting, and abrasive cutting.

4. Pipe Holding and Clamping: To ensure accurate and stable cutting, CNC pipe cutters feature mechanisms for securely holding and clamping pipes in place during the cutting process. This may involve chucks, rollers, or other types of fixtures tailored to the shape and size of the pipes being cut.

5. Axis Control: computer numerical control pipe cutting machine typically operate in multiple axes, allowing for complex cutting patterns and shapes. The number of axes can vary depending on the machine's design and capabilities.

6. Safety Features: Safety is paramount in any industrial machinery, and CNC pipe cutting machines are no exception. These machines often incorporate safety features such as emergency stop buttons, protective enclosures, and interlocking systems to prevent accidents and injuries.

7. Material Handling Systems: Some CNC pipe cutters include material handling systems for loading and unloading pipes, minimizing manual intervention and increasing overall productivity.

8. Accuracy and Precision: One of the primary advantages of computer numerical control pipe cutting machine is their ability to achieve high levels of accuracy and precision, ensuring consistent and repeatable cuts even in complex geometries.

CNC Pipe Cutting Machine Applications:

1. Metal Fabrication: CNC pipe cutting machines are extensively used in metal fabrication shops for cutting pipes and tubes made of materials such as steel, stainless steel, aluminum, and copper. They are employed in the production of structural components, frames, and assemblies for industries like automotive, aerospace, and construction.

2. Pipeline Construction and Maintenance: In the oil and gas industry, CNC pipe cutter play a vital role in pipeline construction and maintenance. They are used to cut pipes to precise lengths and angles, facilitating the assembly of pipeline sections and the fabrication of fittings and connectors.

3. Shipbuilding: Shipyards utilize CNC pipe cutting machines for cutting pipes and tubes used in various ship components, including hull structures, piping systems, and ventilation ducts. These machines ensure accurate fabrication of pipe sections, reducing assembly time and improving overall quality.

4. Industrial Machinery Manufacturing: CNC pipe cutting machines are employed in the manufacturing of industrial machinery and equipment. They are used to cut pipes and tubes for hydraulic systems, pneumatic systems, conveyors, and other mechanical components, ensuring precise fit and alignment.

5. Architectural and Structural Engineering: In architectural and structural engineering applications, CNC pipe cutting machines are used to fabricate custom-designed pipe structures for buildings, bridges, and other infrastructure projects. They enable the creation of complex geometries and intricate patterns with high precision.

6. Fabrication of Furniture and Fixtures: CNC pipe cutting machines are utilized in the fabrication of furniture, fixtures, and decorative items made from metal pipes and tubes. They enable the production of customized designs and prototypes with efficient material utilization and minimal waste.

7. HVAC (Heating, Ventilation, and Air Conditioning): In HVAC systems, CNC pipe cutting machines are used to fabricate ductwork and piping components with precise dimensions and configurations. They contribute to the efficient installation and performance of heating, cooling, and ventilation systems in residential, commercial, and industrial buildings.

8. Automotive and Transportation: CNC pipe cutting machines are employed in the automotive and transportation industries for fabricating exhaust systems, chassis components, roll cages, and other tubular structures. They help manufacturers achieve high-quality welds and assemblies with consistent accuracy.

CNC Pipe Cutting Machine FAQ:

Q. What types of cutting methods are used in CNC pipe cutting machines?

Ans: CNC pipe cutters can utilize various cutting methods, including plasma cutting, oxy-fuel cutting, laser cutting, and abrasive cutting. The choice of cutting method depends on factors such as the material being cut, thickness, and desired precision.

Q. What are the advantages of using a computer numerical control pipe cutting machine?

Ans: Some advantages of using CNC pipe cutting machines include:

- High precision and accuracy

- Increased productivity and efficiency

- Reduction in material waste

- Ability to cut complex geometries

- Consistent quality of cuts

- Automation of the cutting process, reducing manual labor

Q. What industries typically use CNC pipe cutting machines?

Ans: CNC pipe cutters find applications in various industries, including metal fabrication, construction, shipbuilding, automotive, aerospace, oil and gas, HVAC, and furniture manufacturing, among others.

Q. What types of materials can be cut using CNC pipe cutting machines?

Ans: CNC pipe cutters can cut a wide range of materials, including steel, stainless steel, aluminum, copper, brass, titanium, and various alloys commonly used in industrial applications.

Q. Can CNC pipe cutting machines handle different pipe sizes and shapes?

Ans: Yes, CNC pipe cutters are designed to handle pipes and tubes of various sizes, shapes, and profiles. They can cut round, square, rectangular, and other custom-shaped pipes with flexibility and precision.

Q. How are CNC pipe cutting machines programmed?

Ans: computer numerical control pipe cutting machine are programmed using CAD/CAM software. Operators create cutting designs and specify parameters such as dimensions, angles, and cutting paths within the software. The software then generates the necessary CNC code to execute the cutting operations.

Q. What safety precautions should be followed when operating CNC pipe cutting machines?

Ans: Safety is crucial when operating CNC pipe cutters. Operators should adhere to safety guidelines provided by the manufacturer, including wearing appropriate personal protective equipment (PPE), ensuring proper machine setup, and following safe operating procedures to prevent accidents and injuries.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry  Call Me Free

Call Me Free