Roller Bench Type Pipe Flame Beveling and Cutting Machine

20000.00 - 50000.00 USD ($)/Set

Product Details:

- Drive Motor Heavy-duty geared induction motor

- Product Type Pipe cutting and beveling

- General Use Industrial pipe cutting, fabrication, process piping

- Material Steel construction

- Type Bench Type Flame Cutting & Beveling Machine

- Capacity Continuous operation for pipes up to 6 meters

- Weight (kg) Approx. 600 kg

- Click to View more

X

Roller Bench Type Pipe Flame Beveling and Cutting Machine Price And Quantity

- 1 Set

- 20000.00 - 50000.00 USD ($)/Set

Roller Bench Type Pipe Flame Beveling and Cutting Machine Product Specifications

- Industrial Blue/Grey

- No

- Torch integrated cooling system

- Oxy-fuel flame cutting and beveling

- Industrial pipe cutting, fabrication, process piping

- Continuous operation for pipes up to 6 meters

- Bench Type Flame Cutting & Beveling Machine

- Approx. 600 kg

- Roller drive with manual/electric option

- Suitable for pipe diameters ranging from 50mm to 1000mm

- Mild steel, carbon steel pipes

- Semi-automatic and manual

- 0.75-1.5 kW electric drive motor

- Simultaneous pipe flame cutting and beveling

- Pipe cutting and beveling

- AC 220V/380V

- Heavy-duty geared induction motor

- up to 30 mm (depending on pipe material)

- Adjustable; 100-1000 mm/min

- Steel construction

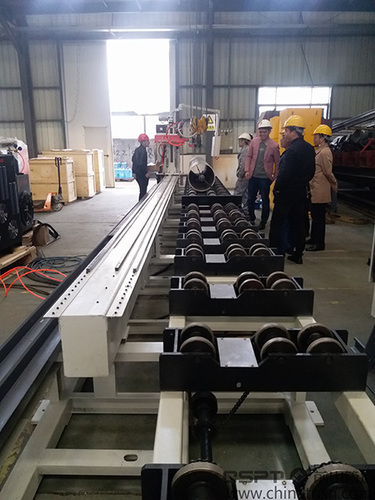

- Roller bench conveyor for smooth pipe movement, robust flame torch

- 3600 x 800 x 1200 mm

- Manual operation; no dedicated controlling software

- 1 mm cutting accuracy

- Manual switch/integrated panel

Roller Bench Type Pipe Flame Beveling and Cutting Machine Trade Information

- 20 Set Per Month

- 45 Days

Product Description

We are instrumental in offering high quality range of excellent functioning Roller Bench Type Pipe Flame Beveling and Cutting Machine. It is manufactured using high grade components and cutting edge technology under the guidance of skilled team of professionals. The offered grader is used for cutting S.S and C.S pipes and is highly demanded in steel, engineering, construction and some other industries . We offer this machine in different specifications to meet the varied needs of clients at reasonable prices.

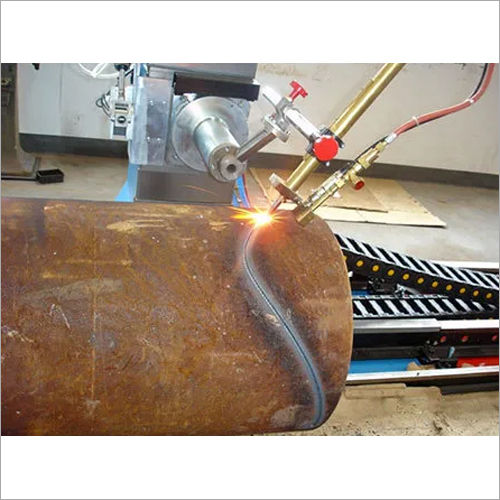

Pipe Flame Beveling and Cutting Machine is designed and manufactured by making use of optimum grade of raw materials and upgraded technology. A persistent magnet wheel is absorbed on steel pipe and used to climb and cut horizontally, vertically, or face-upwardly. This machine is great to use and easy to handle.

Pipe Flame Beveling and Cutting Machine Features:

- Low Carbon steel, alloy steel, and cryogenic steel are among the materials that can be used for manufacturing this machine

- Can cut and bevel any pipe diameter from 100 mm and above.

- This machine is very lightweight, portable, and robust to use

- This takes very little time during setting up

- Pipe Flame Beveling and Cutting Machine cuts up to 100 mm pipe thickness.

- It has excellent incline quality.

- Increased productivity and lower labor expenses, with no need for additional work or grinding

Applications:

- Our provided machine is commonly used in industries such as oil and gas, materials processing, and petrochemicals. This is because the procedure of Pipe Flame Beveling and Cutting Machine is the safest way to cut structures in dangerous locations. The funnel fire inclining and cutting machines online performance is generally great.

Specifications:

- The pipe diameter is widely applicable for this machine

- 6350MM cutting length is required

- Three line steel roller with a fixed distance

- Servo motor along with precision reducer is a great driving system for this machine

- Lengthwise cutting directions are offered

- V-shaped bevel is there

Smooth Precision Cutting and Beveling

Engineered with a multi-position flame torch and adjustable roller bench, this machine ensures consistent, precision cutting and beveling across a variety of pipe diameters and thicknesses. Its robust, powder-coated steel construction offers long-lasting durability even in demanding environments.

Versatile and User-Friendly Operation

Choose between manual and semi-automatic drive for tailored control over your cutting process. The integrated panel and manual switches provide straightforward operation, while the adjustable roller supports guarantee stability for pipes up to 6 meters, enhancing workflow efficiency.

Enhanced Safety and Reliability

Equipped with emergency stop mechanisms, flame guards, and a torch cooling system, safety is prioritized throughout operation. The reliable oxy-fuel flame cutting method and precise mechanical accuracy ensure dependable performance for industrial fabrication and pipe processing tasks.

FAQs of Roller Bench Type Pipe Flame Beveling and Cutting Machine:

Q: How does the roller bench conveyor enhance pipe cutting and beveling?

A: The roller bench conveyor provides stable, adjustable support for pipes, allowing them to smoothly rotate and move during cutting and beveling. This improves accuracy, reduces manual effort, and ensures a uniform finish on pipes up to 6 meters in length.Q: What pipe diameters and materials can be processed with this machine?

A: This machine is suitable for cutting and beveling mild steel and carbon steel pipes with diameters ranging from 50mm to 1000mm. Cutting thickness can reach up to 30mm, depending on the material.Q: When should the torch-integrated cooling system be used?

A: The torch-integrated cooling system operates during cutting to prevent overheating and maintain optimal torch performance, ensuring safety and extending the lifespan of the equipment.Q: Where can this machine be utilized effectively?

A: It is designed for industrial environments such as fabrication workshops, process piping facilities, and pipe manufacturing plants where precision and reliability are crucial.Q: What are the key safety features incorporated in the design?

A: Safety is reinforced with emergency stop buttons, flame guards to shield operators from sparks, and a cooling system to prevent torch overheating during continuous use.Q: How does the adjustable bevel angle benefit pipe fabrication?

A: The adjustable bevel angle from 0 to 45 allows users to tailor the edge preparation for welding and joining, supporting a wide array of pipe configurations and fabrication requirements.Q: Is any special software required to operate this cutting machine?

A: No dedicated controlling software is needed. The machine is operated manually or by using integrated electric controls, making setup and operation straightforward for users.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry