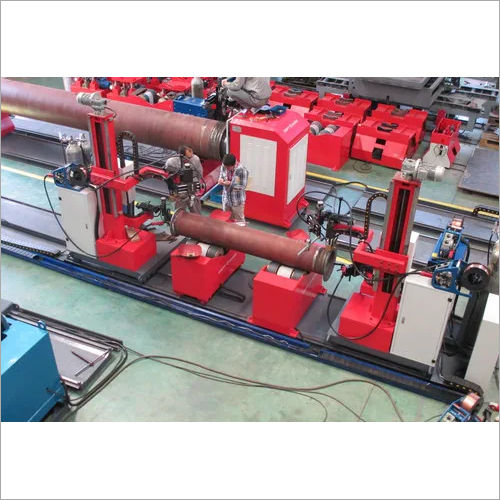

Pipe Flange Welding Machine

25000.00 - 40000.00 USD ($)/Set

Product Details:

- Phase Three Phase

- Power Source Electric

- Automation Grade Semi-Automatic

- Current Range 50-500 A

- Output Voltage 60-72 V

- Power Consumption 7.5 kW/hr

- Diameter Suitable for pipes up to 800 mm

- Click to View more

X

Pipe Flange Welding Machine Price And Quantity

- 25000.00 - 40000.00 USD ($)/Set

- 1 Set

Pipe Flange Welding Machine Product Specifications

- Semi-Automatic

- Mild Steel

- 32 A

- 2000 x 1000 x 1400 mm

- Arc Welding

- 7.5 kW/hr

- 50-500 A

- 60-72 V

- Pipe to flange welding in pipelines & fittings

- Suitable for pipes up to 800 mm

- 380 V

- 50/60 Hz

- Three Phase

- 380 V AC

- Pipe Flange Welding Machine

- Electric

- 7.5 kW

- New

- Electric

- Pipe Flange Welding Machine

- Up to 32 diameter pipes

Pipe Flange Welding Machine Trade Information

- 20 Set Per Month

- 45 Days

Product Description

We are strictly adhere to the guidelines laid by the international standards industry in order to provide high quality Pipe Flange Welding Machine that is extensively used in construction, engineering and allied industries for welding pipes and cover. Our offered grader is manufactured at our modern manufacturing unit under the supervision of our veteran professionals using premium grade components and latest tools and technology. The offered Pipe Flange Welding Machine can be owned at rock-bottom prices.

Advanced Control and User-Friendly Operation

The PLC-based control panel features an intuitive HMI touch screen, allowing operators to precisely adjust welding parameters such as speed, current, and voltage. Digital meters provide real-time feedback, facilitating easy monitoring and setup. The adjustable electrode holder and emergency stop enhance both convenience and operational safety during welding tasks.

Robust Construction and Optimal Performance

Built with mild steel and powder-coated for enhanced rust protection, this welding machine is designed to withstand harsh industrial environments. With an air-cooled torch and IP54 protection class, the equipment offers durability and consistent welding quality, supporting pipe diameters up to 800 mm. The hydraulic clamping system ensures secure fixture positioning for flawless welds.

FAQs of Pipe Flange Welding Machine:

Q: How does the hydraulic clamping system improve the pipe flange welding process?

A: The hydraulic clamping system securely holds pipes and flanges in place during welding, minimizing movement and vibration. This stability ensures accurate weld placement and quality joints, reducing the need for rework and manual adjustments.Q: What pipe diameters and electrode sizes can this welding machine accommodate?

A: This machine is suitable for welding pipes with diameters up to 800 mm and supports electrode sizes of up to 5 mm, offering flexibility for various pipeline and fitting applications.Q: When should I use the emergency stop and thermal protection features?

A: The emergency stop should be activated immediately in case of malfunction, operator safety risk, or abnormal operation. Thermal protection will automatically engage if the machine overheats, protecting components and ensuring safe shutdown until normal operating conditions resume.Q: Where is the Pipe Flange Welding Machine typically installed or used?

A: It is commonly deployed in industrial pipeline construction sites, manufacturing plants, and fitting workshops. Its robust design and adjustable fixture movement suit environments where precise pipe-to-flange welding is required.Q: What steps are involved in operating the Pipe Flange Welding Machine?

A: To operate, secure the pipe and flange using hydraulic clamping, set desired welding parameters via the HMI touch screen, and initiate the welding process. Monitor digital meters for current and voltage readings, and use safety features as needed throughout operation.Q: What are the key benefits of using this welding machine for pipe flange assembly?

A: Key advantages include improved welding precision, adjustable automation for various pipe sizes, robust safety mechanisms, user-friendly operation, and consistent high-quality welds. These features help optimize productivity and reduce operational downtime.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry  Call Me Free

Call Me Free