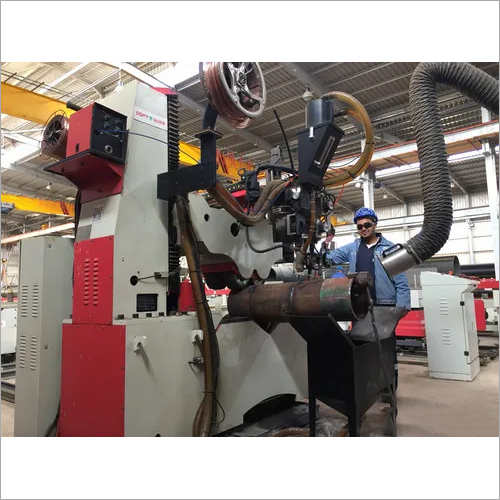

Pipe Welding Equipment

25000.00 - 40000.00 USD ($)/Set

Product Details:

- Usage Butt Welding

- Color Red

- Product Type Pipe Welding Equipment

- Weight 565 Kilograms (kg)

- Condition New

- Motor Type Stepper Motor

- Voltage 380/415/440 Volt (v)

- Click to view more

X

Pipe Welding Equipment Price And Quantity

- 1 Set

- 25000.00 - 40000.00 USD ($)/Set

Pipe Welding Equipment Product Specifications

- Stepper Motor

- 380/415/440 Volt (v)

- 565 Kilograms (kg)

- 600/44/100%

- Red

- Pipe Welding Equipment

- 70-780 Ampere (amp)

- Butt Welding

- New

Pipe Welding Equipment Trade Information

- 20 Set Per Month

- 45 Days

- CE Certified

Product Description

We are widely accepted name in industry in manufacturing, exporting and supplying Pipe Welding Equipment. This equipment is manufactured in accordance with set international quality standards using quality-approved components under the vigilance of our diligent professionals. Our offered equipment is widely used for fabricating and welding pipes and is designed to reduce labor charges. Our offered equipment is made available in various specifications to fulfill the varied requirements of our clients. The offered Pipe Welder can be owned from us at rock-bottom prices.

When it comes to high-quality welding, having the right equipment is crucial. Introducing our advanced Pipe Welding Machine, designed to elevate your welding capabilities to new heights. With its cutting-edge features and exceptional performance, this equipment is your key to achieving precise and efficient welds.

Our Pipe Welding Equipment is meticulously engineered to meet the demands of various welding applications. From small-scale projects to large industrial operations, this versatile equipment adapts to your needs with ease. Whether you're working with stainless steel, carbon steel, or other pipe materials, this equipment delivers consistent and reliable results.

Featuring state-of-the-art technology, our Pipe Welder offers advanced automation features that streamline the welding process. This automation ensures precise control over key welding parameters, such as voltage, current, and wire feed speed, resulting in impeccable weld quality. Say goodbye to guesswork and hello to accurate and repeatable welds.

Safety is always a top priority, and our Pipe Welding Equipment exceeds industry standards. Equipped with comprehensive safety features, including protective shields, emergency stop buttons, and fault detection systems, it ensures a secure working environment for operators. You can weld with confidence, knowing that your team is protected at all times.

What sets our Pipe Welding Machine apart is its unmatched efficiency. By automating time-consuming tasks and optimizing welding parameters, it significantly reduces production time. This efficiency translates into cost savings and increased productivity, allowing you to take on more projects and meet tight deadlines without compromising on quality.

Versatility is another hallmark of our Pipe Welding Equipment. With its adjustable settings and compatibility with various welding techniques, such as TIG, MIG, and stick welding, this equipment caters to a wide range of applications. Whether you're working in construction, manufacturing, or maintenance, this equipment is your go-to solution for precise and efficient welds.

Investing in our Pipe Welder is an investment in the success of your welding operations. By harnessing the power of cutting-edge technology, you can elevate your business to new heights. With its exceptional performance, reliability, and efficiency, you gain a competitive edge in the industry and deliver superior welds that meet the highest standards.

Don't settle for average welding equipment. Upgrade to our Pipe Welding Machine today and experience the difference it makes in your welding projects. Contact us now to learn more about this innovative equipment and how it can transform your welding operations for the better.

Pipe Welding Equipment Specifications:

1. Pipe Diameter Applicable: DN50-600 (60-610)

2. Pipe Wall Thickness Applicable: 3-30mm

3. Pipe Length Applicable: 400-8000mm (for pipe dia <400 mm, adopt to auxiliary method to welding)

4. Clamping System: Clamping arm move up and down by screw

5. Control System: PLC control and indication by text display

6. Rated Capacity: 600/44/100%

7. Rated Duty Cycle: 600/44/100%

8. Welding Type: Automatic Butt Welding

9. Core Components: PLC, Engine, Motor

10. Control System: PLC

11. Certification: CE

12. Video outgoing-inspection: Provided

13. Machinery Test Report: Provided

14. Warranty of core components: 2 years

15. Warranty: 2 years

16. Applicable Materials: Carbon steel, alloy steel , stainless steel and cryogenic steel

Pipe Welding Equipment FAQs:

Q. What is a pipe welding equipment?

Ans: This machine is a specialized piece of equipment used to join sections of pipes together by welding. It provides the necessary power and control to fuse pipes efficiently.

Q. What types of pipe welding equipments are available?

Ans: There are various types of pipe welding equipment, including manual, semi-automatic, and automatic machines. Manual machines require the welder to control the welding process entirely, while semi-automatic and automatic machines offer varying degrees of automation.

Q. What are the benefits of using a pipe welding equipment?

Ans: These machines offer increased efficiency, consistency, and precision in the welding process. They also help reduce labor costs and ensure high-quality welds, resulting in stronger and more reliable pipe joints.

Q. How do I choose the right pipe welding machine for my application?

Ans: Consider factors such as the type and diameter of pipes you'll be welding, the welding process (e.g., stick welding, TIG welding, MIG welding), required welding output, and desired level of automation. Consult with a welding expert or supplier to select the most suitable machine for your needs.

Q. What safety precautions should I take when using a pipe welding equipment?

Ans: Always wear appropriate personal protective equipment (PPE), such as welding helmets, gloves, and safety glasses. Ensure proper ventilation in the welding area to prevent exposure to harmful fumes and gases. Follow manufacturer's instructions and adhere to all safety guidelines.

Q. How do I maintain a pipe welding equipment?

Ans: Regular maintenance is essential to ensure the optimal performance and longevity of your pipe welding machine. This includes routine cleaning, inspection of components for wear or damage, lubrication of moving parts, and calibration of controls as needed.

Q. Can a pipe welding machine weld different materials?

Ans: The capability of a pipe welding equipment to weld different materials depends on its welding process and specifications. Some machines are designed specifically for certain types of materials, while others may offer versatility for welding various metals such as steel, stainless steel, and aluminum.

Q. What training is required to operate a pipe welding equipment?

Ans: Proper training and certification are essential for safe and effective operation of a pipe welding machine. Welders should undergo comprehensive training in welding techniques, machine operation, and safety protocols to ensure proficiency in their work.

Q. What is the typical cost of a pipe welding equipment?

Ans: The cost of a pipe welding machine can vary widely depending on factors such as brand, model, specifications, and additional features. Prices can range from hundreds to thousands of dollars for both new and used machines.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry  Call Me Free

Call Me Free