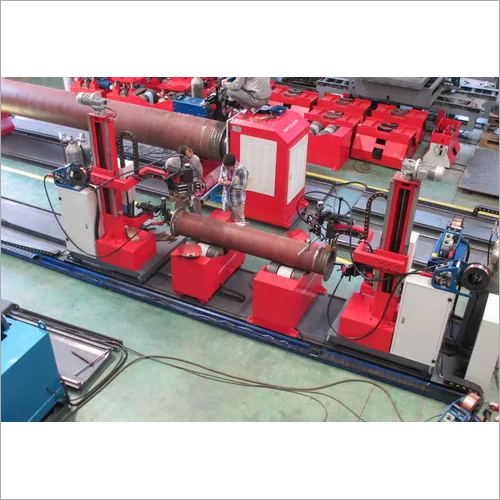

Slip On Flange Automatic Pipe Welding Machine

25000.00 - 40000.00 USD ($)/Set

Product Details:

- Diameter Pipe: 50 mm 600 mm

- Automation Grade Fully Automatic

- Frequency 50 Hz

- Current Range 30A 500A

- Application Automatic welding of slip-on flange to pipe

- Equipment Type Pipe Welding Machine

- Power Consumption Low

- Click to View more

X

Slip On Flange Automatic Pipe Welding Machine Price And Quantity

- 25000.00 - 40000.00 USD ($)/Set

- 1 Set

Slip On Flange Automatic Pipe Welding Machine Product Specifications

- Fully Automatic

- Automatic welding of slip-on flange to pipe

- Pipe Welding Machine

- 380V AC

- 30A 500A

- Slip On Flange Automatic Pipe Welding Machine

- Supports pipe diameters: 50 mm 600 mm

- 1950 x 800 x 1350 mm

- 10 kW

- 380V

- Mild Steel / Stainless Steel

- New

- Pipe: 50 mm 600 mm

- 50 Hz

- Electric

- Electric

- Automatic MIG/ARC

- Three Phase

- 45A

- Low

- 20V 50V

Slip On Flange Automatic Pipe Welding Machine Trade Information

- 20 Set Per Month

- 45 Days

Product Description

Automatic Slip-On Flange Welding Machine is mainly utilized to weld the slip-on flange's inside and outside fillet seams. It has outstanding welding capabilities. And the operability is excellent. When used in conjunction with a two-axis flame/plasma cutting machine and a motorized pipe and flange fitting-up equipment, it may create a production line.

Automatic Slip-On Flange Welding Machine Features:

Automatic Slip-On Flange Welding Machine Features:

- Fill the fillet weld by MAG/TIG welding multi-gauge pipe and slip-on flange together.

- Not designed for production line operation

- The welding criteria can be met if the fusion depth and width are good and smooth.

- Very good operability is there

- The welding gun will always be positioned in the optimum position

- Automatic Slip-On Flange Welding Machine is easily handled

- The use of CO2/ MIG/ SAW is optional.

- This machine is used for flange and pipe welding. Slipi on Flange for the internal and external incidence angle welding line. This machine has excellent welding quality and efficiency. This machine is checked under industrial parameters to ensure its high quality and long-lasting durability.

- Welds Applicable: Welding line of flange pipe

- 3-30MM is the pipe wall thickness required

- One welding head with two welding guns at one end/two welding heads with four welding guns both at two ends

- Adjustment Mode: Electric cross regulator

- Clamped by chain or contact roller

- A product of our patented technology, driven by step motor and oscillating adjusting with digital display

Advanced Welding Precision

The machines three axis precision torch adjustment ensures seamless alignment during the welding process, which significantly improves weld quality and consistency. The hydraulic automatic clamping secures the pipe and flange, minimizing movement for precise circumferential welds every cycle.

User-Friendly Digital Control Panel

Its intuitive digital control panel offers clear operational visibility and accessible parameter adjustments. Programming the welding sequence, monitoring welding speed, and setting electrode types becomes straightforward, allowing operators to adapt to different pipe sizes and welding requirements with ease.

Robust Safety and Durability Features

Powder-coated surfaces enhance the machines resistance to corrosion, making it suitable for demanding industrial settings. Safety featuresincluding emergency stop, overload protection, and noise control (<75 dB(A))ensure worry-free operation while supporting long equipment life.

FAQs of Slip On Flange Automatic Pipe Welding Machine:

Q: How does the automatic pipe welding machine ensure precise welding for slip on flanges?

A: The machine utilizes PLC-controlled automation, hydraulic clamping, and three-axis torch adjustment for precise alignment. Automatic rotation provides uniform circumferential welding, guaranteeing consistent, high-quality welds for slip-on flanges.Q: What pipe diameters can be accommodated by this welding machine?

A: This equipment supports pipes with diameters ranging from 50 mm to 600 mm, enabling versatility for various industrial piping applications.Q: When should the welding speed be adjusted on the machine?

A: Welding speed, adjustable between 0 and 1000 mm/min, can be set based on material type, thickness up to 30 mm, and desired welding outcome. Operators benefit by customizing settings for optimal weld penetration and minimization of defects.Q: Where can this automatic pipe welding machine be installed?

A: It is designed for use in manufacturing facilities, fabrication workshops, and large-scale pipe installation sites due to its heavy-duty build and compatibility with industrial power sources (380V AC, 3-phase).Q: What is the process for operating the automatic flange welding machine?

A: Operation involves clamping the pipe and flange using the hydraulic system, setting welding parameters on the digital panel, and initiating the automated welding cycle. The machine manages electrode feed, torch positioning, rotation, and cooling automatically.Q: How does the cooling system contribute to machine performance?

A: The integrated water-cooled system prevents overheating during extended welding sessions, ensuring reliable performance and prolonging the service life of vital components.Q: What are the main benefits of using this slip on flange automatic pipe welding machine?

A: Users gain improved welding quality, reduced manual labor, consistent output, enhanced safety features, and adaptability to different pipe materials and sizes, making it a valuable solution for high-volume, precision welding tasks.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry  Call Me Free

Call Me Free